The Problem With Coal

The problem with coal and a new high-tech solution…

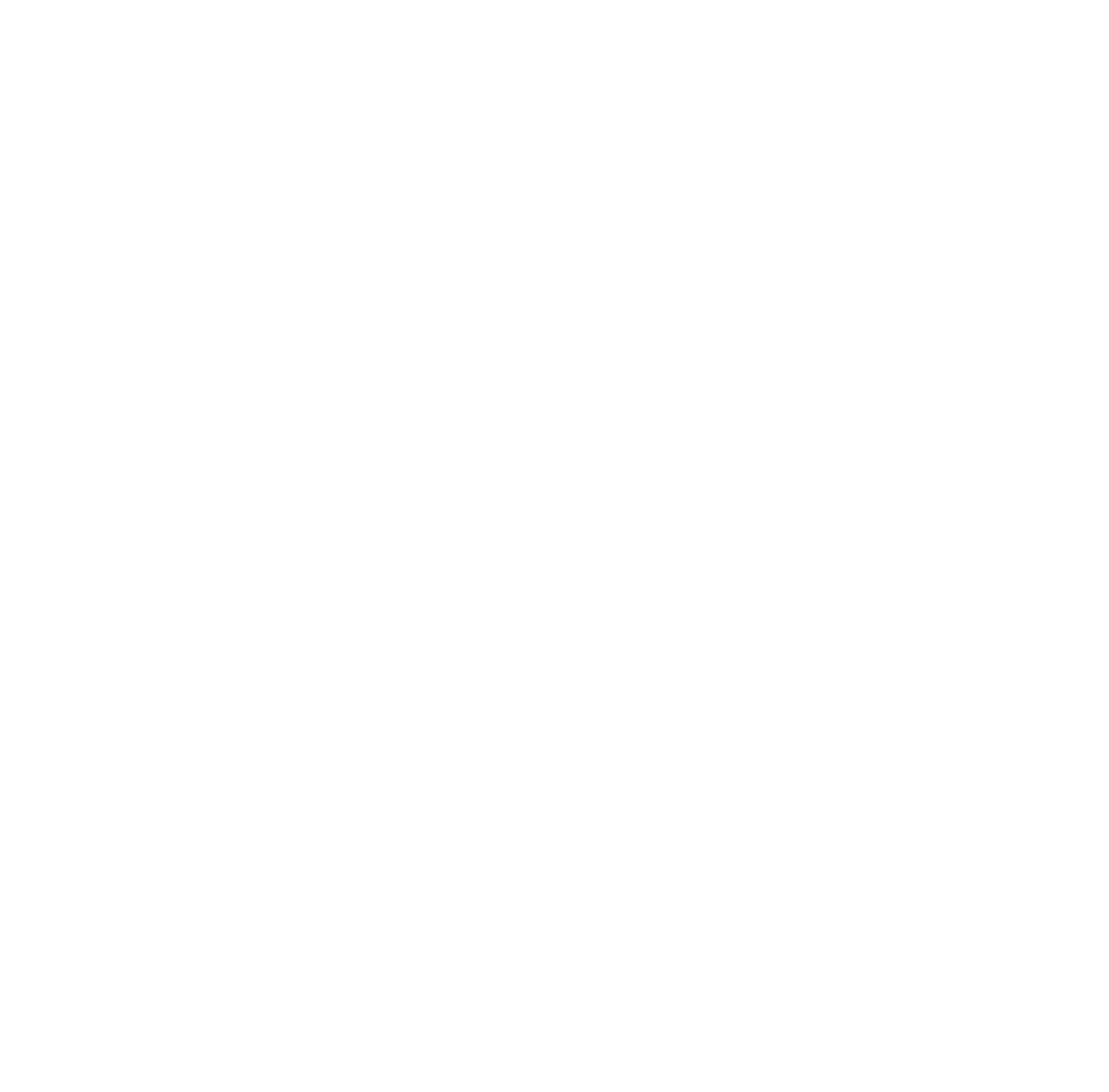

Disruptive Technology Created By Accident

For more than 3 centuries people around the world have hated and even feared coal, but almost 65% of countries still use it today in 2025, even after more than 800,000 lives have been lost mining it and another 6.2 million died from cancer after inhaling coal dust from the tailings. Yet it remains the most abundant and relatively affordable fossil fuel mined in 39 countries and exported worldwide. It is a $2.5 Trillion-dollar industry and even still growing in the BRIC nations. In Africa, Pakistan, India, and Central Asia coal is essential to daily life and without it people’s diet would be low protein and food poisoning rates would be through the roof from uncooked foods and meats… Surprisingly, roughly 20% of Americans still rely on coal for their heating and/or cooking needs. The world’s first mining of coal as a fuel source goes back thousands of years to ancient China (Ming dynasty) and even the Roman Empire. Back then nobody knew of the various health, safety, and environmental dangers of coal. The only benefit of coal is what mattered at the time when winter temperatures arrive to their housing that had no insulation. Today in the world, coal generates 40% of all electricity and this amazing infographic will show you who is using the most and least coal from 1965 to 2023 as demand for black rock continues to grow.

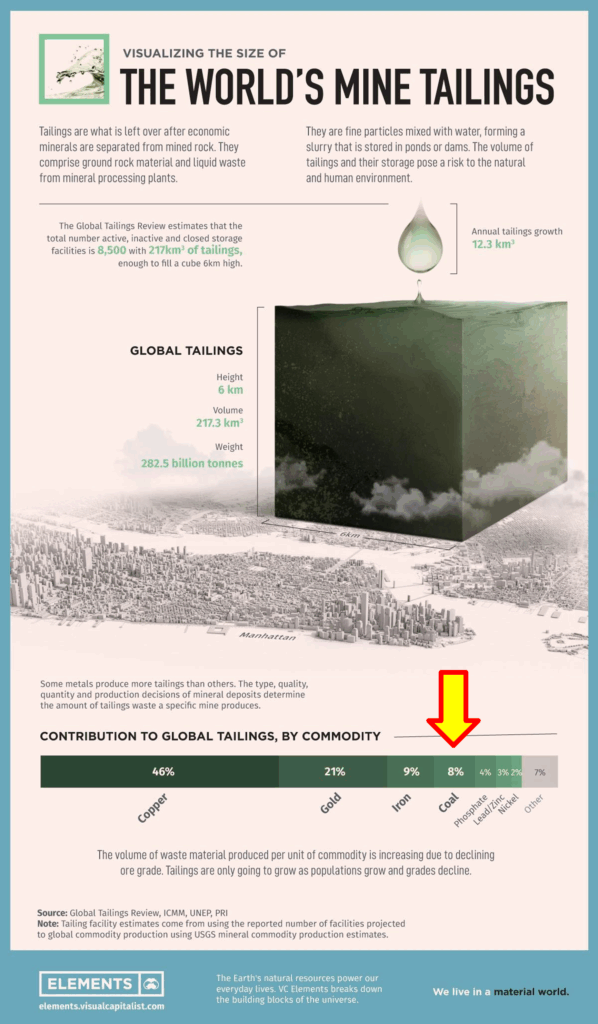

However, the BIGGEST problem with coal today in 2025 is what remains when a mine is closed or exhausted by its resources. All the coal refuse (drilling dust called “tailings”) accumulates by the ton, and it is both a health and fire hazard that does not just go away after time. It took mother nature millions of years to create coal, but she intended for it to remain underground. On the surface this fine and very toxic coal dust, ranging in size from .5 to 100+ microns (even smaller than this period.) has until the 1990s, remained piled in mini mountains around the world, or buried in deep pits. Since man first began mining coal commercially in 1590, over 16 billion tons of these tailings have accumulated in North America alone. And if somehow, they could be recycled, they could power the Earth for the next 15-25 years. In Europe (especially Russia, Ukraine, U.K. and Poland another 30+ Billion tons of tailings have accumulated. This coal refuse not only created huge health, safety, and environmental risks and actual damage, but also caused quite a few dam failures and related problems.

The EPA and governments changed how tailings must (or should be stored) since they discovered the wind was carrying coal dust aloft all around the world and their citizens living within a 150-mile radius of a mine site had soaring cancer rates (12%-20% increase). The toxins within the coal granules were leaching into the ground water as well. Their solution required mine operators to dig deep “Slurry pits, beds, or pond” some as deep as 200 feet and line them with a thick plastic tarp to stop to prevent toxic chemicals from leaching into the soil and ground water. Tons of tailings are now dumped into these pits, but the surface tailings are still subject to wind gusts, so the EPA mandates that they be always kept wet, also to prevent spontaneous ignition which is also a problem when temperatures get above 65 degrees F. This maintenance of slurry pits is not cheap and may cost a mine owner more than $500,000 to comply and maintain government standards. Only in North America and 4 European countries is enforcement a real consequence. Bribes to government inspectors are a lot cheaper to pay elsewhere. Here below is a photo of relatively new coal tailings before being dumped into a slurry bed or pit.

While coal usage has slowly been declining in the United States, production has steadily been increasing all over the world to keep up with the growing demands of undeveloped and countries who cannot afford to go nuclear nor have the desire/will or economic resources for green alternative energy. But at least now they can have much greener and cheaper coal, IF producers want to pass the manufacturing cost savings along to the end users or share the extra profits with regional distributors and local wholesale/retail suppliers.

But, until now this “solution” is just a band-aid and still does not get rid of the tailings in a safe, nor healthy way. Now there is indeed a safe and healthy way to not only dispose of the coal tailings, but also the toxic “fly ash” coal leaves behind after it is burned, an equally huge and expensive problem discussed in part two. Disposal fees have been turned into recycled profits with even higher profit margins than the original coal that created its problematic refuse that truly is or was an environmental nightmare. Below is a typical and highly toxic coal tailings pond or slurry bed…

The ugly eyesores not only pose health and safety risks to humans and wildlife, but they currently litter countries around the world with an estimated ground coverage of over 3,500 square miles of wasteland that economically drain the wallets of mining companies in maintenance, compliance and sanction costs. imposed by governments. More than 300 of these tailing ponds can be found in Kentucky, Pennsylvania, Ohio, and West Virginia alone.

A 65-year-old American 3D artist working in China was looking for a light but sturdy art medium that would allow him to create wall and mounted 3D sculptures and art works that would not structurally stress walls, be cheap, and 60% lighter than clay and other faux clay alternatives. His artwork was becoming known and buyers wanted larger (and much heavier works) to be installed in their homes, offices, and sides of entire buildings. By experimenting with a variety of botanical and other organic materials he accidentally discovered what he now calls “Green Goop” that could save over 1 billion trees annually and replace more than 90% of wood, 40% of plastics, and even 32%-40% of steel products.

Because this artist was also a trainer with many engineering students, the teacher quickly became a student of his pupils and got a crash course in materials and structural engineering. Here is the “accidental artist” who due to his political whistle- blowing more than 30 years ago, created and sold his works under a pseudonym to avoid being tainted in the art world. An American Ai Weiwei if you will.

In recent months, it was also discovered, again by accident, that 2 of the organic ingredients, when specially mixed, processed, and cured with coal tailings, can produce the cleanest burning coal in the world with less than .025 of Sulphur content, the real villain of coal content. This recycled coal is not just cleaner than lump coal taken directly from a mine, but about 30%-50% cheaper, provides the same BTU ratings, can burn longer and is far SAFER to make than to mine coal! (No human needs to risk their health nor lives underground ever again) Nor will another coal strip mine ever need to scar our environment like those found in Colombia, Brazil and even parts of America and 23 other countries where it is still allowed and ongoing.

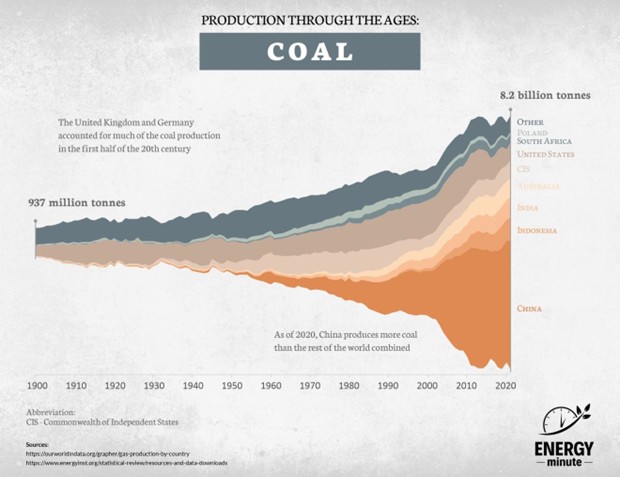

Before the coal tailings can be recycled, they must be rinsed and dewatered as seen below. Equipment mounted in three 53-foot tractor trailer trucks can produce up to 18,000 metric tons of clean coal daily using proprietary methods and ingredients and either bagged for resale or loaded directly into rail cars or waiting 30-ton dump trucks for immediate delivery and use.

And when yet another organic ingredient is added, fly-ash can be cheaply converted into a strong and suitable aggregate to extend or even replace the dwindling world supply of “clinker” used in making concrete and could be adapted to strengthen and extend asphalt with a slight modification as well.

“Coal can be a blessing rather than a curse if we put global resource management into a green sustainable program and restructure the coal markets with tariff-free incentives”.

– The Inventor

From this dreaded disposal nightmare below, fly ash can become an extremely profitable product in the concrete/cement industry

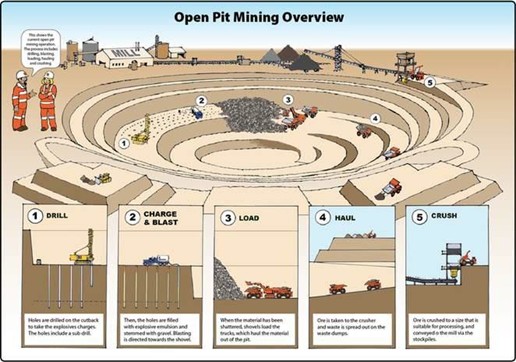

Any smart government that wants to take the lead in coal exports or become the noble green leader in setting a new clean energy trend only needs to offer a cleaner and cheaper alternative and quickly grab the lion’s share of the new world coal market. This could be accomplished through various business models including exclusive licensing or establishing a tariff-free market for certified “green coal” products. Even a country like Mongolia, given the proper leadership and financial development support, could dominate the coal industry of Asia given its unique location between Russia and China, cheap labor, and their famous rail lines. Indeed “Green Coal” could be a real game changer in world energy markets.

Even non-coal producing countries like Japan could capitalize on this disruptive technology simply by providing international service companies if their pockets are deep enough and their leaders wise enough to seek and secure exclusive service contracts with their fleet of special service trucks.

This new recycled “green coal” can also be used to make longer-burning charcoal briquettes like these pictured below or used to make “pitch tar” to extend asphalt and produce it more economically.

Best of all, the recycled coal made from tailings can be recycled on-site (eliminating prohibitive transportation costs) and produced in any shape or size ranging from golf-ball sized pellets, barbecue briquettes, to bricks, to traditional sliced cylinders used for cooking, hookah, disaster relief, and camping/survival. Once a slurry bed has been reclaimed, the area can be filled in and replanted with profitable growth, such as Japanese and Korean Yew trees used for making an expensive cancer-treatment drug (Taxol) adding to the revenue stream of the slurry bed while eliminating the liabilities and mandated maintenance costs.

In most cases new technology is born in laboratories by scientists working in teams on their research for years sponsored by universities with huge endowments or Fortune 500 giants like 3M, Dow Chemical, Exxon, etc. In this case a 65 year-old Coast Guard veteran and his hobby and passion for 3D art fueled his accidental discovery of a material used in this 3D work of his that put his imagination into over-dive, After speaking with others already dabbling on with the coal and fly ash problems, he began doing research of his own, not as a scientist, but as a “greenie” who believes every fuel source can be made greener if we have the will to do so.

References

https://www.statista.com/topics/1051/coal/

https://phys.org/news/2019-05-coal-ash-tailings-disasters.html

https://globaltailingsreview.org/wp-content/uploads/2020/09/Ch-II-Mine-Tailings-Facilities_Overview- and-Industry-Trends.pdf

https://www.nature.com/articles/s43017-024-00576-4

https://www.science.org/doi/10.1126/science.aax1927

https://www.treehugger.com/environmental-effects-of-mine-tailings-1204114

https://elements.visualcapitalist.com/visualizing-the-size-of-mine-tailings/

https://enviroliteracy.org/what-are-the-environmental-impacts-of-coal/

https://phys.org/news/2019-05-coal-ash-tailings-disasters.html

https://theconversation.com/weekly-dose-taxol-the-anticancer-drug-discovered-in-the-bark-of-a-tree- 56508