Green Goop™ – Replacing Wood, Plastic, and Concrete

NEW DISRUPTIVE TECHNOLOGY SAVES TREES AND REPLACES CONCRETE

The new Disruptive Green Tech Can Save Over 1 billion Trees Annually and Reduce Plastic & Concrete Use

With over 10,000 trees being consumed by the lumber industry every hour, and another 500,000 by wildfires every year. The price of Plywood and other lumber has increased 377% just from 2020 to 2021. By 2025 the shortage of affordable lumber will be critical and very expensive, and it is projected by the UN and FEMA that only 30% of the world's population will be able to buy their own home.

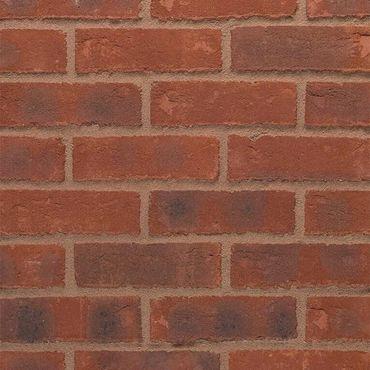

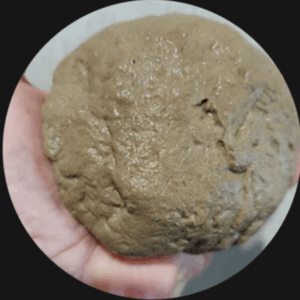

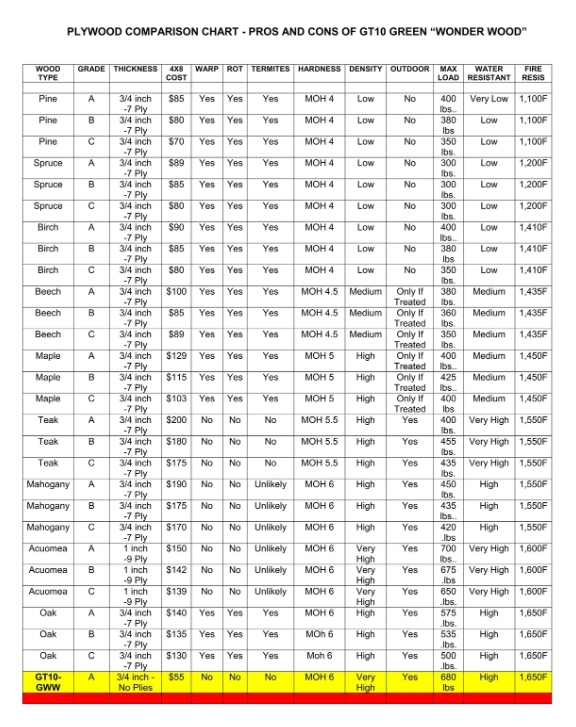

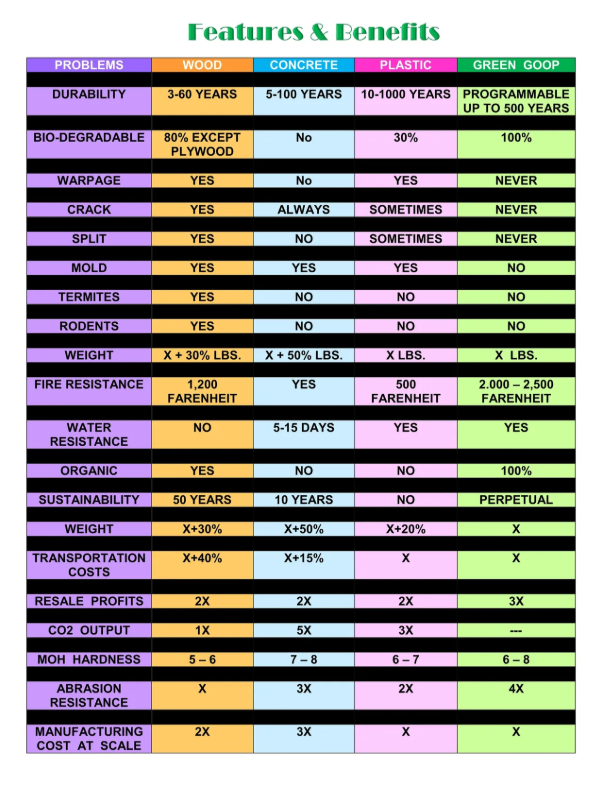

But the material you see here are samples of a new Green Material (now being trademarked) is not only stronger and 30%-70% cheaper than natural wood, it is made from 100% recycled organic waste, but termites won't eat it, and it can be made both in waterproof, fire-proof, and even bullet-proof versions. Science and technology have gone green.

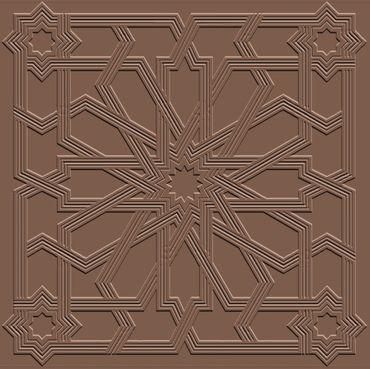

This green wonder wood can be molded, pressed, extruded, nailed, screwed, painted, stained and there is no shortage of the raw materials used to make this new material. All the products you see below can be made from this "green goop" which contains no chemicals and is so safe, the inventor will eat it for you! See the videos below, and you will understand WHY the market value of this material is now $91 Billion and will exceed $100B by 2025.

This new green building material was discovered by accident while a 3D artist was searching for a light but strong and cheap replacement for clay to make his wall sculptures and papier mâché was just too fragile. He was doing an exhibition in China at the time, so he experimented with discarded harvest waste and other local organic materials he obtained for free, or almost free. The result was something that looks like clay, but when dry, is as hard as a maple baseball bat, it doesn't warp, but is 50% lighter, yet remains 100% bio-degradable!

One formulation of this new material we call "Green Crete" is 23% stronger than Portland Cement without the cracks and environmental pollution problems seen in the video below "Our Concrete Problem". The only thing in this world that people use more than water is concrete, and there is no more destructive material on Earth than concrete. Learn why in this video:

Green Goop™ – Replacing Wood, Plastic, and Concrete

Disruptive Material Innovation from Organic Waste

▶️ Watch the Demonstration Video

See how Green Goop™ is transforming sustainable manufacturing. Note: proprietary trade secret steps have been omitted to protect confidentiality.

10-Minute Process Overview

Green Goop™ is made using a proprietary blend of plant-based waste materials. It requires only hot water and ambient curing, no chemical agents, high heat, or harmful additives.

- Blend organic ingredients

- Add hot water to activate natural binders

- Press or mold the mixture into shape

- Let it cure at room temperature (ambient)

Detailed Application Sections

3D-Printed Housing

Green Goop™ Formula 7 integrates with concrete printers to form internal panels, insulation, and finish layers. Its flexibility and moldability allow for intricate geometries and surface textures, resulting in stronger, lighter, greener buildings.

Automotive

Green Goop™ can be used in door panels, dashboards, and battery housing. It’s safer, lighter, and completely petroleum-free—ideal for EV innovation where sustainability matters.

Marine

Its waterproof and anti-corrosive nature makes it perfect for boat decking, docks, and submersible structures. It does not leach toxins, ensuring environmental safety in marine ecosystems.

Plastics

The bio-degradable Green Goop™ Formula 6 is designed to reduce roughly 40% of the world’s plastic consumption.

Defense

Formula 8 is bulletproof and flame-retardant, perfect for barriers, shields, crates, and mobile equipment. It replaces metal or resin-based composites with a safer, reusable alternative.

Infrastructure

Green Goop™ can be extruded into sewer pipes, panels, utility poles, or fencing systems. It handles compression, exposure, and moisture without degradation.

Wind Energy

Green Goop™ can be used to manufacture turbine blades that are recyclable three times and biodegradable at the end of their life. This is a true circular economy solution to blade landfill problems.

Consumer

Manufacture packaging, furniture, cabinetry, and decor. It is Paintable, sandable, and joinable like wood—but safer and cleaner. Dyes and textures can be added during formation.

Wind Turbine Blade Case Study

Blades made from fiberglass and thermosets cannot be economically recycled. Green Goop™ blades, however, can be mechanically reprocessed three times, then safely biodegraded.

The Inventor’s Story

Developed by a sculptor looking for a safe material for large-scale art, Green Goop™ became a mission-driven discovery. The result is a sustainable, trade secret material outperforming traditional construction and packaging inputs.

ASK

The inventor offers exclusive regional and global licensing opportunities or complete acquisition of proprietary technology.

This is a rare opportunity to license and operate localized production facilities or purchase the technology outright.

The inventor is seeking interested parties ready to scale, commercialize, and lead the market with this disruptive technology saves trees and meets world demands for dwindling resourses.

📞 Contact

Eileen Durfee

Email: [email protected]

Phone: 509-670-9713

Green Goop Videos

So WHAT'S IN THIS STUFF?

100% Organic Waste - Compliments of Mother Nature

The ingredients of this new material are 100% organic, contain no chemicals, and are all recycled waste matter that is accumulating around the world quickly. No plastics are used and full disclosure will be made to prospective strategic partners at demos. It’s consistency is similar to soft clay before use and becomes as hard as rock after it dries. All ingredients are 100% bio-degradable.The annual world value of this material is estimated at $100 Billion USD annually as summarized below;

Why not just keep using trees to make wood?

For three very good reasons...

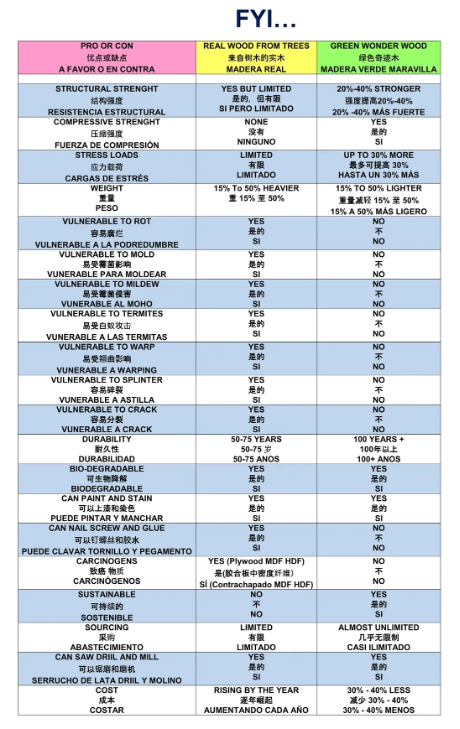

Because by 2030 the only adult tree forests we will have will be in National Parks and due to the laws of supply and demand, the price of lumber will increase more than 500% by then, and even today our green "Wonder Wood" is already 30%-50% cheaper to make and up to 40% stronger.

We need our trees for 22 other much more important purposes that you probably do not know about https://www.treepeople.org/22-benefits-of-trees/

Our forests are home to over 40 species of animals and 7 of them are endangered species.

Besides, we also have BIG problems with plastic and concrete as well. And with slight modifications the new green material can replace most of all concrete and about 40% of the plastics we use daily in our lives. Mother Nature gave us a very pleasant and useful surprise!

This IS THE NATURAL COLOR OF THE MATERIAL

Most COMMON QUESTIONS...

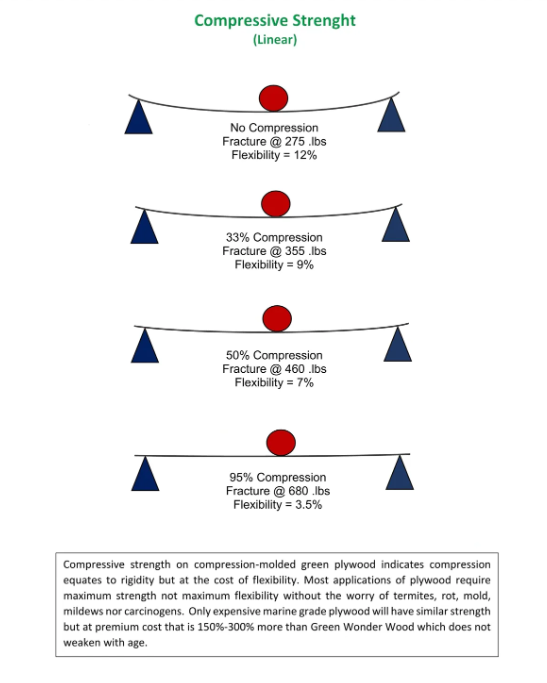

Our material is a composite of multiple ingredients all of which vary in hardness. On the MOH scale, our final combined hardness is 6.0 which is about as hard as a Maple wood baseball bat. See here for comparisons https://www.ianknapper.com/infographic/mohs-stone-hardness-scale-infographic/ Most HDF (High Density Fiberboard) rates at 3 to 4. But remember, hardness does not equal strength nor durability, and in this regard we excel. Structures made from our lumber or bricks may endure for up to 200-300 years if properly used and sealed.

Most notably we are about one-third to one-fifth the cost of plywood. And for the purpose of home-building or pouring concrete structures, there is no reason to spend so much. Furthermore, termites will eat plywood that is not chemically treated. Nobody wants toxic chemicals (nor termites in their home). Plywood also warps and dries out over time. Eventually it will rot or disintegrate depending on climate/humidity. Plywood also uses glues or resins which are also chemicals and prevents plywood from being biodegradable. All our products are 100% biodegradable. Also, unlike plywood products that contain toxic carcinogens (formaldehyde and glues, our material is chemical-free.

Our material has a natural color of a light tan to a dark brown, depending on the formulation. Used. You can stain or paint our finished product any color you like or just seal it in its natural earth-tone color.

First, those materials use trees (wood chips) while our material saves trees by using other organic materials. Secondly, both MDF and HDF use chemicals and are therefore not 100% biodegradable. We do not use any chemicals and are 100% bio-degradable - and sustainable. We are far more durable than both MDF and HDF. You will not find 300-year-old products made from MDF or HDF. Our manufacturing costs are the same as HDF.

https://www.fullspectrum.org.uk/index.php/kirlian-energy-fields/ https://www.healthline.com/health/what-is-an-aura#who-has-it https://pubmed.ncbi.nlm.nih.gov/20619734/ http://www.breakthru-technologies.com/technologies/bio-active-systems https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2076531/ https://www.youtube.com/watch?v=cxdCU-xOSa8 https://www.auraphoto.com/fundamentals/whatis/ https://www.researchgate.net/publication/324136632_Bio-Inspired_Materials_Contribution_of_Biology_to_Energy_Efficiency_of_Buildings

Exciting Information

Green Goop can replace 90% of WOOD products, 60% of CONCRETE products, and 70% of PLASTIC products

From millions of Railroad Ties to Fuel-Saving Ship & Boat Hulls, to Car Body Panels, to Wind Turbine Blades, the applications for this new disruptive material are limited only by our imagination and ingenuity. There are even a dozen military and space applications.

Next Steps

Green Goop™ is available for exclusive licensing or acquisition. This trade secret-protected technology is ready for commercialization across high-impact sectors.

Contact us to schedule a private demonstration under NDA.

Email: [email protected]

Phone: 509-670-9713